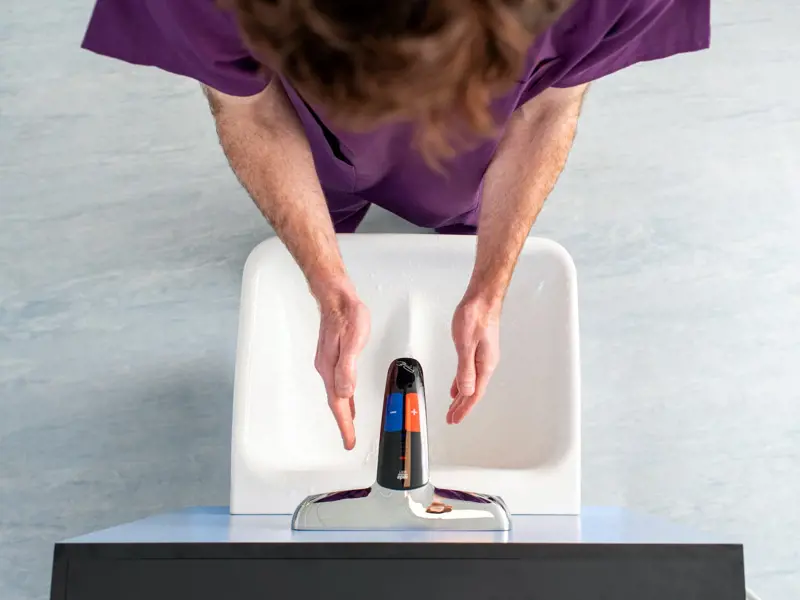

All Intelligent Care taps undergo comprehensive air testing to reduce the risk of bacteria proliferation between leaving the factory and installation in the hospital or healthcare facility. In fact, Rada Controls’ Intelligent Care taps are all leak tested using oil-free compressed air – a safer and more reliable alternative to the standard compressed air typically used during the air testing of other products. With no water required during the thermal testing procedure, the risk of moisture or water being introduced into the tap during the assembly process is therefore reduced.

Ensuring bacteria hasn’t formed is essential

Given that products can often be left on a merchant’s shelf for an extended period of time before being purchased and installed, knowing that bacteria is much less likely to have formed inside the taps or pipework gives real peace of mind.

Efficient and comprehensive air testing undertaken in the factory is a highly effective way of reducing the risk of bacterial proliferation between leaving the factory and installation elsewhere.

This is hugely important, especially with the taps likely to be installed in healthcare premises where bacteria and infection control are absolutely paramount.

Adhering to healthcare guidance

With the Health Technical Memorandum (HTM) stating that leak testing should be undertaken using nitrogen, medical-quality compressed air, or oil-free compressed air, and by competent personnel, ensuring adherence to these guidelines is hugely important.

The oil-free compressed air testing carried out by Rada Controls on all of its Intelligent Care taps will help meet the HTM 04-01 guidance, with all testing taking place without the need for water including thermal calibration testing. As a result, the risk of moisture forming in the tap, pipework, or fittings is reduced.

A market-leading product with bacteria control at its core

Air testing is a vital aspect of any tap’s manufacture. However, equally as important is the quality of the product. With that in mind, it’s vital that any healthcare facility or hospital specifies market-leading products that focus on bacteria control.

Rada Controls’ Intelligent Care taps feature programmable duty flushing and thermal disinfection as standard. Additionally, these thermostatic taps are all digitally calibrated to desired temperatures without the need for water testing, and comprehensively tested in the factory, using oil-free compressed air. For further information, visit the Intelligent Care section of our website. Alternatively, if you’d like to discuss the Intelligent Care air testing process further, contact our customer support team today on 0344 571 1777.

Find our more about our air tested products

Intelligent Care – Full Air Tested

Intelligent thermostatic high basin tap with non-touch flow (IR) and temperature (capacitive) controls, smooth bore copper outlet pipe with open bore flow insert, copper tails, programmable temperatures, run time, automated blend duty flush and cold flush, thermal disinfection, integral 12 month data log and optional connection to building network systems.

Intelligent thermostatic basin tap with non-touch flow (IR) and temperature (capacitive) controls, smooth bore copper outlet pipe with open bore flow insert, check valve/filter unit, copper tails, programmable temperatures, run time, automated blend duty flush and cold flush, thermal disinfection, integral 12 month data log and optional connection to building network systems.

Intelligent thermostatic basin tap with non-touch flow (IR) control, smooth bore copper outlet pipe with open bore flow insert, copper tails, programmable temperatures, run time, automated blend duty flush and cold flush, thermal disinfection, integral 12 month data log and optional connection to building network systems.

Intelligent thermostatic basin tap with non-touch flow (IR) and temperature (capacitive) controls, smooth bore copper outlet pipe with open bore flow insert, check valve/filter unit, pex lined hoses, programmable temperatures, run time, automated blend duty flush and cold flush, thermal disinfection, integral 12 month data log and optional connection to building network systems.

Intelligent thermostatic basin tap with non-touch flow (IR) control, smooth bore copper outlet pipe with open bore flow insert, check valve/filter unit, PEX lined hoses, programmable temperatures, run time, automated blend duty flush and cold flush, thermal disinfection, integral 12 month data log and optional connection to building network systems.

Intelligent thermostatic panel mount tap with non-touch flow (IR) and temperature (capacitive) controls, smooth bore copper outlet pipe with open bore flow insert, check valve/filter unit, programmable temperatures, run time, automated blend duty flush and cold flush, thermal disinfection, integral 12 month data log and optional connection to building network systems.

Our Sports and Leisure Projects

We’re already helping sports and fitness facilities to achieve five-star reviews with leading washroom facilities.